Mon - Fri 7:00 am - 4:30 pm

601 South Palm Ave, Alhambra, CA 91803

Posted by [email protected] No Comments on Elastomeric Metal Roof Coating: A Comprehensive Guide Uncategorized

Elastomeric Metal Roof Coating: A Comprehensive Guide

Elastomeric metal roof coatings are protective layers applied to metal roof surfaces to enhance durability and performance. This comprehensive guide delves into the benefits, application processes, and considerations needed to maximize the advantages of elastomeric coatings on metal roofs.

Understanding Elastomeric Metal Roof Coating

Elastomeric coatings are specialized products designed to protect and extend the life of metal roofs. They form a seamless, durable barrier against the elements, safeguarding roof surfaces from weather damage, corrosion, and UV radiation.

Key Benefits and Advantages

Applying elastomeric coatings to metal roofs brings numerous benefits, including:

1. Improved Roof Longevity: Extends the life of metal roofs.

2. Reduced Maintenance Costs: Minimizes the need for repairs.

3. Enhanced Energy Efficiency: Reflective properties reduce energy costs.

4. Aesthetic Appeal: Improves the overall look of buildings.

Reflectivity and Energy Efficiency

Elastomeric coatings are highly reflective, helping to reduce roof surface temperature. This reflectivity translates into lower energy costs by reducing the need for air conditioning, making buildings more energy-efficient and comfortable during hot weather.

Durability and Longevity

Elastomeric coatings can withstand extreme weather conditions, resist cracking and peeling, and significantly extend the life of metal roofs. This makes them an economical choice for long-term roof protection.

The Science Behind the Coating

Elastomeric coatings are engineered to offer superior protection for metal roofs. Their formulation provides excellent weather resistance, while their elasticity allows them to expand and contract with temperature changes, preventing damage.

Weather Resistance

These coatings withstand weather conditions, including heavy rain, hail, and extreme sunlight. Their weather resistance helps maintain the integrity of roof surfaces, protecting them from leaks and other damage.

Elasticity and Flexibility

The elasticity and flexibility of elastomeric coatings are key to their performance. They can move with the metal roof during temperature fluctuations without cracking, ensuring continuous protection against moisture and environmental damage.

Selecting the Right Elastomeric Coating for Your Metal Roof

Choosing the correct elastomeric coating depends on roof conditions and local climate. Understanding these aspects helps select a product that will provide the best protection and durability for metal roofs.

Factors to Consider

– Roof Condition: Assess any rust, leaks, or damage that needs addressing.

– Expected Weather Exposure: Choose coatings with features suited to the climate.

– Maintenance Requirements: Understand the maintenance needs of the coating.

Climate and Environmental Conditions

Areas with high temperatures or intense sunlight require coatings with excellent UV resistance and reflectivity to ensure energy efficiency and durability.

Roof Condition and Preparation Needs

Proper surface preparation is crucial. Any rust, leaks, or damage should be addressed, and the roof must be cleaned to ensure the coating adheres well.

Comparison: Premium Brands and Their Unique Features

Different brands offer elastomeric coatings with unique features tailored to specific needs. Comparing these can help identify the most appropriate option for a metal roof’s requirements.

Roof Seal Premium Elastomeric Coating

Known for its exceptional durability and flexibility, it provides a waterproof barrier that resists weathering and UV damage, making it ideal for protecting metal roofs in various climates.

CeramaX Heat Reflective Waterproof Coating

Noted for its thermal insulation properties, its ceramic technology reflects heat, significantly reducing cooling costs and improving indoor comfort during warmer months.

RainArmor System

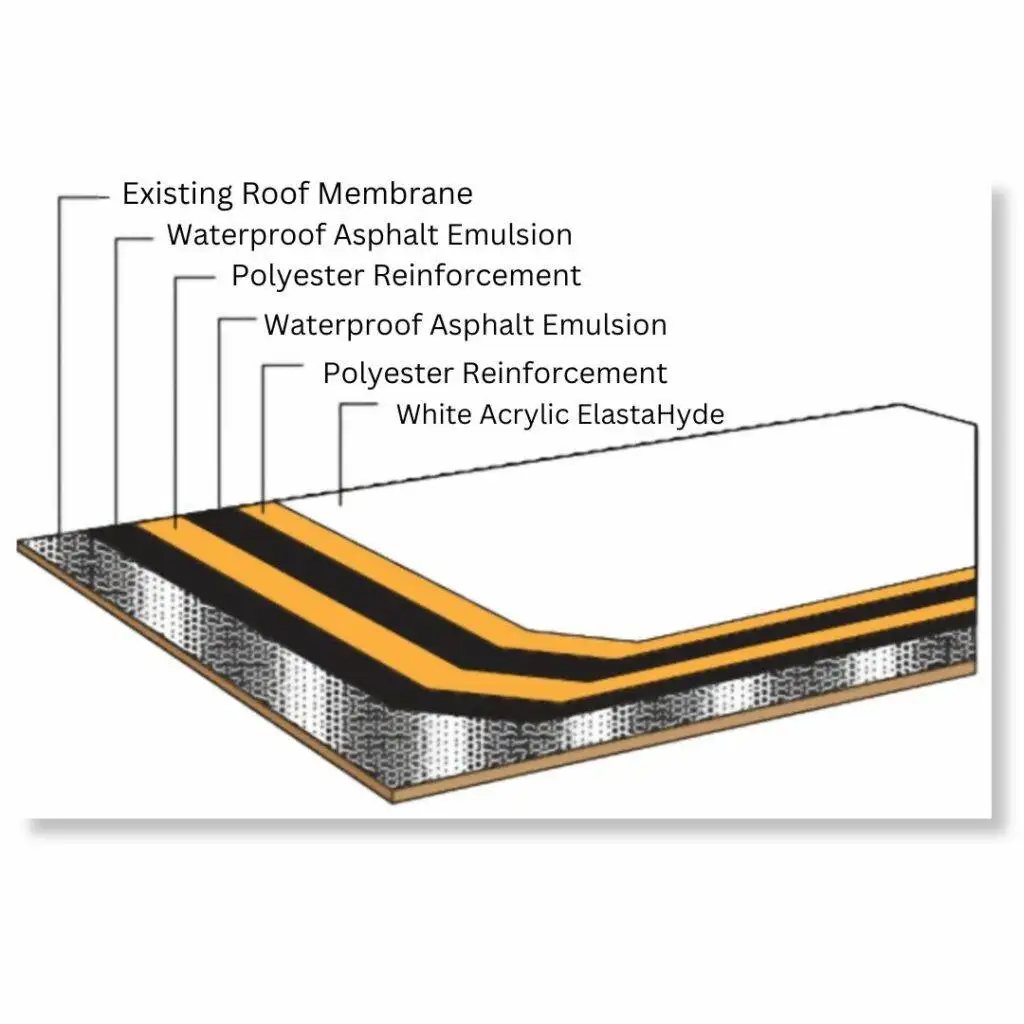

Cost-effective and of superior quality, ensuring no leaks and providing peace of mind during heavy rainstorms. Excellent customer service guarantees a smooth installation process. RainArmor Roofing Systems have revolutionized the commercial roofing landscape with lightweight, high-performance, and sustainable Cool-Roof solutions. Widely endorsed by major corporations and property managers, these systems offer unmatched waterproofing, reinforcement, and reflectivity. What sets RainArmor apart is its affordability, which does not compromise on quality, guarantees no leaks, and provides peace of mind during heavy rainstorms.

The installation process is streamlined, as removing the old roof is unnecessary, making it faster and easier. Developed initially for military installations in the 1940s and still a top choice for schools and commercial buildings, RainArmor combines single-ply and built-up roofing features for unparalleled durability. Their systems include waterproofing asphalt, high-strength polyester reinforcement, and a two-phase acrylic elastomeric surface to block UV radiation and reflect heat. Long-lasting and eco-friendly, RainArmor roofs significantly lower energy costs while ensuring a robust roofing solution that stands the test of time.

Application Techniques and Best Practices

Applying an elastomeric coating to metal roofs requires skill, precision, and adherence to best practices to ensure longevity and effectiveness. Every step, from initial surface preparation to final application, is crucial.

Surface Preparation: The First Step to Success

Clean the roof to remove dirt, debris, and any rust. Ensure the roof is completely dry and free of contaminants to ensure the coating adheres appropriately and provides the intended protection.

Detailed Application Process

Professionals aim for a uniform thickness across the entire roof surface. The process involves applying a primer (if necessary) and the elastomeric coating using a brush or roller. Special attention is given to fasteners and seams to seal them adequately.

Tools and Equipment Needed

Essential tools include a high-quality brush or roller, a sprayer for larger areas, seam rollers, caulk guns for sealing fasteners and seams and measuring tools to apply the coating at the correct thickness.

Step-by-Step Application Guide

1. Clean and Dry the Roof Surface: Remove all dirt, debris, and rust.

2. Repair Damages: Address any existing damage on the roof.

3. Apply Primer (if necessary): To improve adhesion.

4. Apply Elastomeric Coating: Using a brush or roller, apply evenly, focusing on fasteners and seams.

5. Layering: Apply in layers, allowing sufficient drying time between each layer.

Caring for Your Coated Metal Roof

Maintaining the coating is critical to extend its lifespan and maintain its protective qualities. Regular inspections are necessary to identify any cracks or damages early. Cleaning the roof to remove debris and mildew helps maintain the coating’s integrity over time.

Maintenance Tips for Longevity

– Periodic Inspections: Check for signs of wear or damage.

– Timely Repairs: Address any issues promptly.

– Cleaning: Remove dirt and debris regularly.

– Follow the Manufacturer’s Guidelines To avoid damaging the coating.

Inspecting and Repairing Your Elastomeric Coated Roof

Focus on areas where the coating has deteriorated or been damaged, particularly around fasteners and seams. Use compatible repair materials to ensure continued performance and protection.

Innovative Roof Coating Systems

Innovative roof coating systems offer varying levels of protection tailored to different climatic conditions and roofing needs. These systems range from basic waterproofing to advanced, multi-layered coatings that provide superior energy efficiency and durability.

Good, Better, Best: Choosing Your Protection Level

– Good System: Basic waterproofing and durability, suitable for mild climates.

– Better System: Improved reflectivity and resistance to weathering, suitable for more demanding conditions.

– Best System: Advanced technologies for maximum energy efficiency, longevity, and extreme weather resistance. (See RainArmor System)

Mild Climate Solutions: The “Good” System

Provides adequate protection against basic environmental factors. It focuses on waterproofing and preventing leaks, offering a cost-effective solution for extending the life of metal roofs.

Four-Season Protection: The “Better” and “Best” Systems

The “Better” system incorporates increased reflectivity and durability, while the “Best” system employs advanced technologies for unparalleled energy efficiency and weather resistance. These systems ensure comprehensive protection for metal roofs in all seasons.

Case Studies: Transformations Achieved with Elastomeric Metal Roof Coating

Numerous case studies showcase dramatic improvements in waterproofing, energy efficiency, and overall roof performance. Buildings with chronic roof leaks and deteriorating existing roofs have been revitalized, significantly reducing cooling costs and enhancing aesthetic and functional attributes.

Wrapping Up: Ensuring a Successful Elastomeric Coating Project

Ensure all steps have been meticulously followed, starting with proper surface preparation. Confirm that there’s adequate ventilation in the area to foster efficient drying and curing of the coating. These details contribute to the longevity and effectiveness of your roof’s coating.

Professional Consultation and Services

Consulting with professionals can significantly enhance the project’s success. Experts understand how expansion and contraction affect metal roofing systems and ensure the chosen coatings are compatible and will perform well. Their expertise can help you achieve a durable, long-lasting roof coating, safeguarding your investment.

Recent Posts

Categories

Recent Posts

Tags

Do you have any questions?

Contact us at The HP Roofing PRO office or submit a business inquiry online

Contact Us