Mon - Fri 7:00 am - 4:30 pm

601 South Palm Ave, Alhambra, CA 91803

Posted by thomas ferriere No Comments on What Are the Benefits and Myths of Silicone Roof Coatings? Roofing

What Are the Benefits and Myths of Silicone Roof Coatings?

Roofs don’t have many jobs to do. Staying in place and not leaking is about the long and short of it. Wear and tear on your warehouse roof is the last thing on anyone’s mind… until you find a puddle on the floor under a mysterious drip. Thankfully we live in a world of fantastic technological advancements, and the roofing industry hasn’t been left behind. Silicone roof coatings are a quick and potentially cost-effective solution to ensuring both an easy fix and preventative measure to all your leaky-roof needs.

But how do silicone coatings measure up? How reliable can a layer of silicone be, anyway? Surely it can’t be this simple!

Keep reading and we’ll explore this mystery together!

What Is Silicone, Anyway?

How much do you know about silicone roof coatings?

You’re familiar with the tubes of calk most commonly found at the back of an unused drawer or cupboard. You’ve wondered at the lines of silicone around windows and the bathtub where it meets the tiles.

What is this magical substance? It’s ubiquitous wherever there’s a need to create a water-resistant seal where two edges meet. So it’s strange you’ve never given it much thought, right? We’re in the same water-repellent boat, there. Thanks to silicone, that is.

Typically speaking silicone is a colorless, odorless, rubber-like substance broadly used for all sorts of applications such as sealants, adhesives, insulation, medicine… and maybe even your favorite spatula.

But Why Silicone Roof Coatings?

The reason silicones are well respected and relied upon in so many and varied applications is due to their special qualities as a whole. It’s these properties in combination that make it such a popular and effective solution.

For example, and this is by no means an exhaustive list:

It’s resistant to oxygen, ultraviolet light, and microbiological growth such as molds. It’s practically inert in terms of its chemical reactivity, has low toxicity, is water repellent, and has a curious interaction with surfaces, sticking happily to some and with great difficulty to others.

It can also be stored for a long time and has an ease of application second to none.

In combination, it’s not hard to appreciate why this stuff is everywhere!

So What About My Roof, Then?

Well, at this point I’m sure you can understand the benefits of silicone roof coatings. A match made in heaven. You want a roof that doesn’t leak, and silicone doesn’t want anything other than to behave as it does naturally, which just happens to be what you want, too!

Imagine the scenario. The roof you’ve known and loved (and probably barely given much thought to at all before disaster struck) has sprung a leak. Do you run out and buy a new roof, throwing your old, loyal roof into the bin? That’s a costly option. But you know better than to do that. Reduce, reuse, recycle!

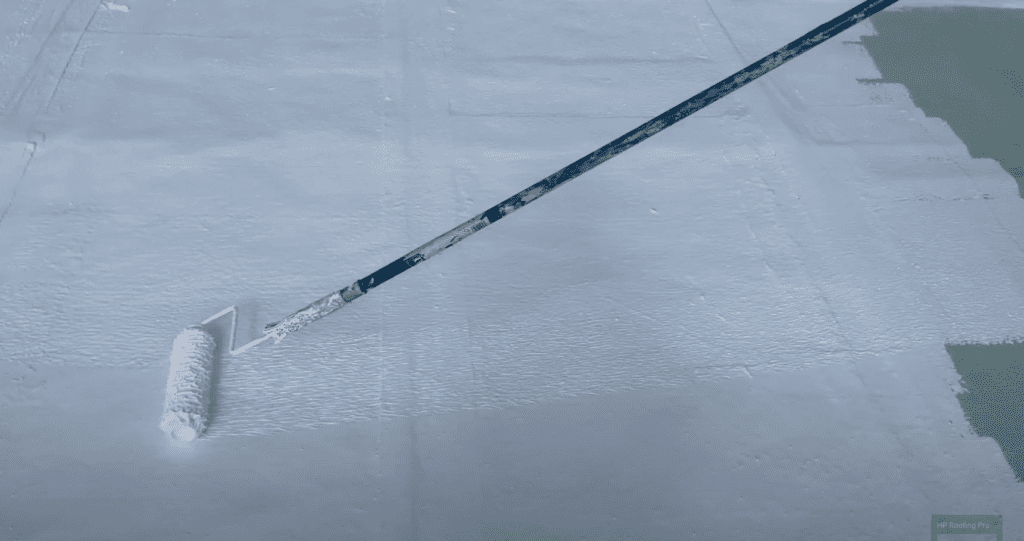

You can revitalize that roof with a relatively inexpensive silicone roof coating. Same old roof, no new leaks. One less headache and all it took was a bucket of silicone and an old paint roller.

Silicone Myths

Coming along hand in hand with silicone’s ease of use and application are a few old soundbites that have dug their way into the public psyche that aren’t completely true.

Leftover from marketing schemes and advertising, some properties of silicone have been over-exaggerated. This doesn’t mean silicone isn’t a wonderful solution for a lot of problems, it’s just best not to get carried away. Which is, when it comes to silicone, completely understandable.

Though it’s best to appreciate exactly what this substance can withstand and how it really responds in the wild without gilding the facts.

Waterproof Silicone

You may have heard that silicone is completely waterproof, which isn’t true. In fact, silicone can be more accurately described as water-resistant or repellent. Water can indeed penetrate through silicone given enough time due to not being completely impervious to hydrostatic pressure.

While sounding less than ideal, the ability for roof coatings to breathe a little is actually what the industry prefers. This allows any trapped moisture to leave the underlying layers of its construction. Without a little ‘breathing room,’ the chance of dry rot and mold problems increases.

A roof isn’t a single barrier, it’s usually a collection of layers, each with a different job to do. A single layer of silicone isn’t sufficient for waterproofing a roof, but it does act as a superb additional layer of protection.

Nothing Sticks

Its use in the building industry has propagated myths concerning its use in tandem and in proximity to other similar substances, especially in relation to their reactions to one another. It’s commonly believed that nothing sticks to silicone, which isn’t true.

There’s some science behind this, so bear with me. Cement, paints, bituminous, and asphaltic roof solutions all have higher surface energy than set silicone does. Put simply, the higher the substrate surface energy the easier it is to adhere to.

Silicones generally have low surface energy, making them hard to adhere to, but not impossible. This also makes them rather slippery and less than ideal to walk upon whilst wet, so try to choose somewhere other than a silicone-treated roof for your morning stroll if it’s been raining.

Home and Dry!

If this is your first foray into researching the potential benefits and usage of silicone roof coatings, it’s pretty simple. Used as an extra layer of protection, to patch a leak, or to give your roof an extra lease on life, you can’t go wrong.

If you’re curious, check out some of our video case studies for the use of silicone roof coatings to better understand their application in commercial use!

Recent Posts

Categories

Recent Posts

Do you have any questions?

Contact us at The HP Roofing PRO office or submit a business inquiry online

Contact Us